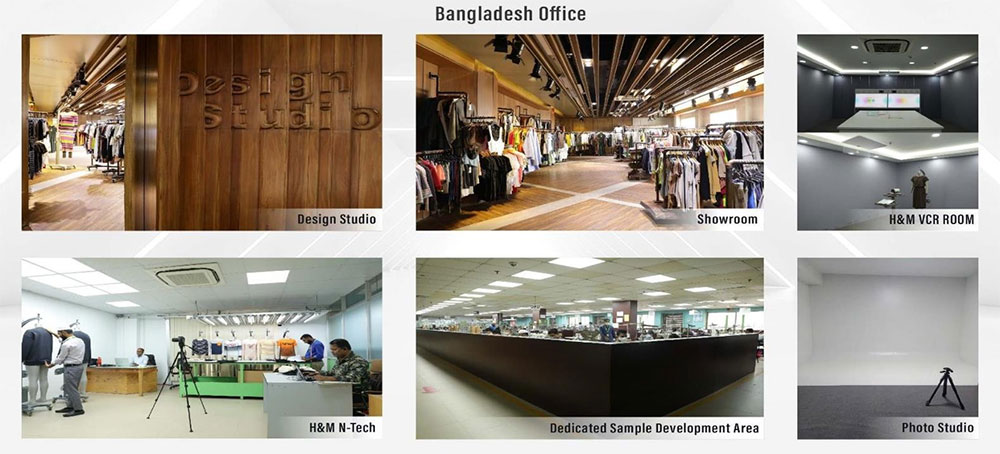

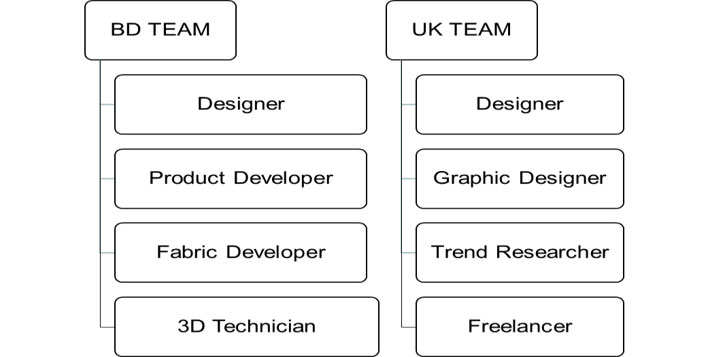

Our design studio and its development capabilities is deeply rooted on creative values and its appreciation. We use state-of-the-art technology for ongoing research and development purposes keeping the latest fashion trend at the heart of our designs.

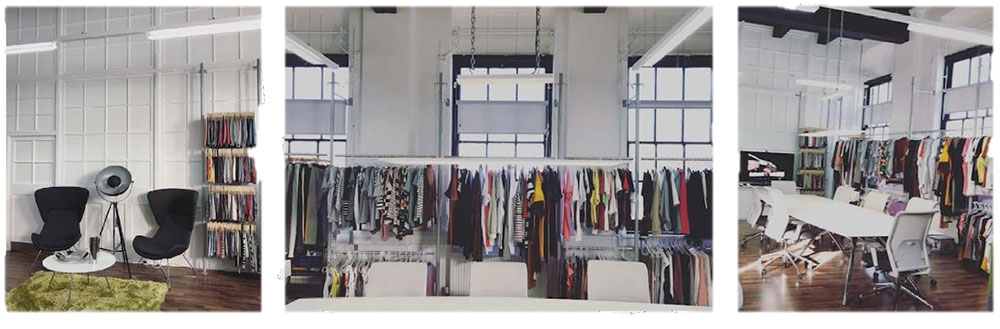

To meet our esteemed buyers’ requirements, we have a dedicated design team and studio based in United Kingdom, the epicentre of Fashion.

We are continuously upgrading our product development segment. Innovation is the core driving factor that we utilize in terms of achieving pole position within the Apparel Manufacturing sector. Additionally, this enables us to focus on sustainable fashion.

FFL Physical Testing Lab is conducting tests on

various fabric quality requirement from the buyers. It

has the capability of testing according to International

Standards Methods of tests for Textile & Garments,

such as: ISO, BS & EN.

FFL has a variety of knit fabrics including spandex and dyed yarn options as well as follows:

Colour expresses personality, FFL’s dyeing & dyeing finishing is well equipped with updated European machineries. These machines are a technological masterpiece using Total Dye-House system software called Sedo Master & TDH.

“Dyeing Finishing is the final stages of fabric processing. In FFL we have state of the art fabric finishing machineries. We are capable of reproducing multi-functional finishing effects on the fabrics by consuming less water and energy aiming towards sustainable production processes. Some of the special functional finishes are anti-bacterial, flame retardant, water repellent,

anti-pilling, anti- creasing, sanforizing, anti-fiber migration etc.”

FFL Washing Department boosts to have world class machineries stacked with unique process capabilities

such as Natural Dyeing Acid, Cold Pigment Dyeing, Tie Dyeing Dip, Deep Dyeing, Enzyme Wash, Reactive Dyeing, Direct Dyeing,

Normal Wash, Grinding, Dyeing, Dyeing Spray, Wash Pigment, Wash Crinkle Acid, and many more Washing processes.

Our Washing Plant is built with environment conscious state of the art machineries from Yilmak, Jianye, JY Honda,

Yokohama, Chungmoon, Gison, Makita and many more. In terms of ensuring Sustainable production processes, our Washing

department is no different. We ensure compliance standard and beyond processes such as our Natural Dyeing process

uses recycled raw materials.

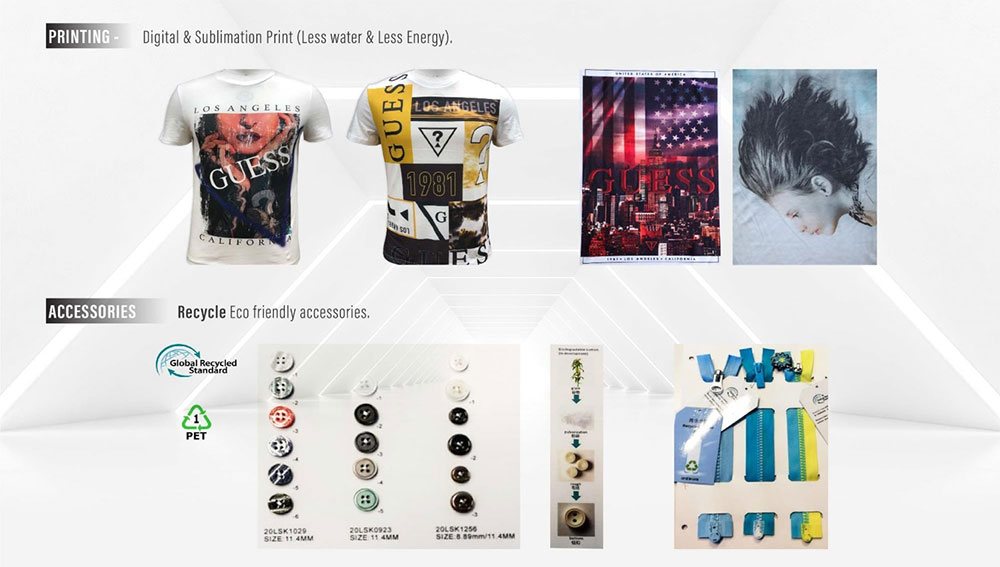

FFL has placement and transfer print capability which can print on rubber, pigment/water base, Hi-density, gel, flock, discharge, plastic sole, glitter etc.

Our independent lab in Printing department conducts physical test, print durability, rubbing, PVC tests to ensure quality and robustness.

Basic, Sequin, Applique, Bids, Corrding etc.

Among many types of machines we also have:

Quality is a debatable matter but at FFL the buck stops as per the requirement of the buyer which is deemed to be the final decision in terms of quality. There’s no room to compromise in it!

FFL Quality Promise: “We are committed to achieve optimum customer Satisfaction with best Quality readymade garments through effective

Quality Management System and continuous improvement by complying with the guidelines of customer.”